RATIONALIZATION, DISCRETIZATION & EFFICIENT FABRICATION

The use of computer-aided-design software tools in architectural and product modelling has shattered the former connection between brain and object usually established by the use of hands in the making process. The emergence of numerical control machinery has allowed the designer to close again this circle in a fully digital process. Data is transformed from bits to matter through code.

Digital Fabrication is composed of a first block dedicated to geometry rationalization. Acknowledging architecture is discrete, and industrial material are mainly planar, different rationalization techniques are studied to reparametrize surfaces of arbitrary double curvature into planar pieces. The second block is focused on subtractive 3D manufacturing where instead of designing an object to be milled, students are encouraged to design the milling process that will define the object.

df.2d machining

Planar subtractive operations with 2d cutting tools:

Digital seminar: Geometry bootcamp.

Physical seminar: Topology and curvature with guest expert teacher.

Digital seminar: Topology workshop: foundations of remeshing.

Digital seminar: Optimization and evolutionary multi-criteria optimization.

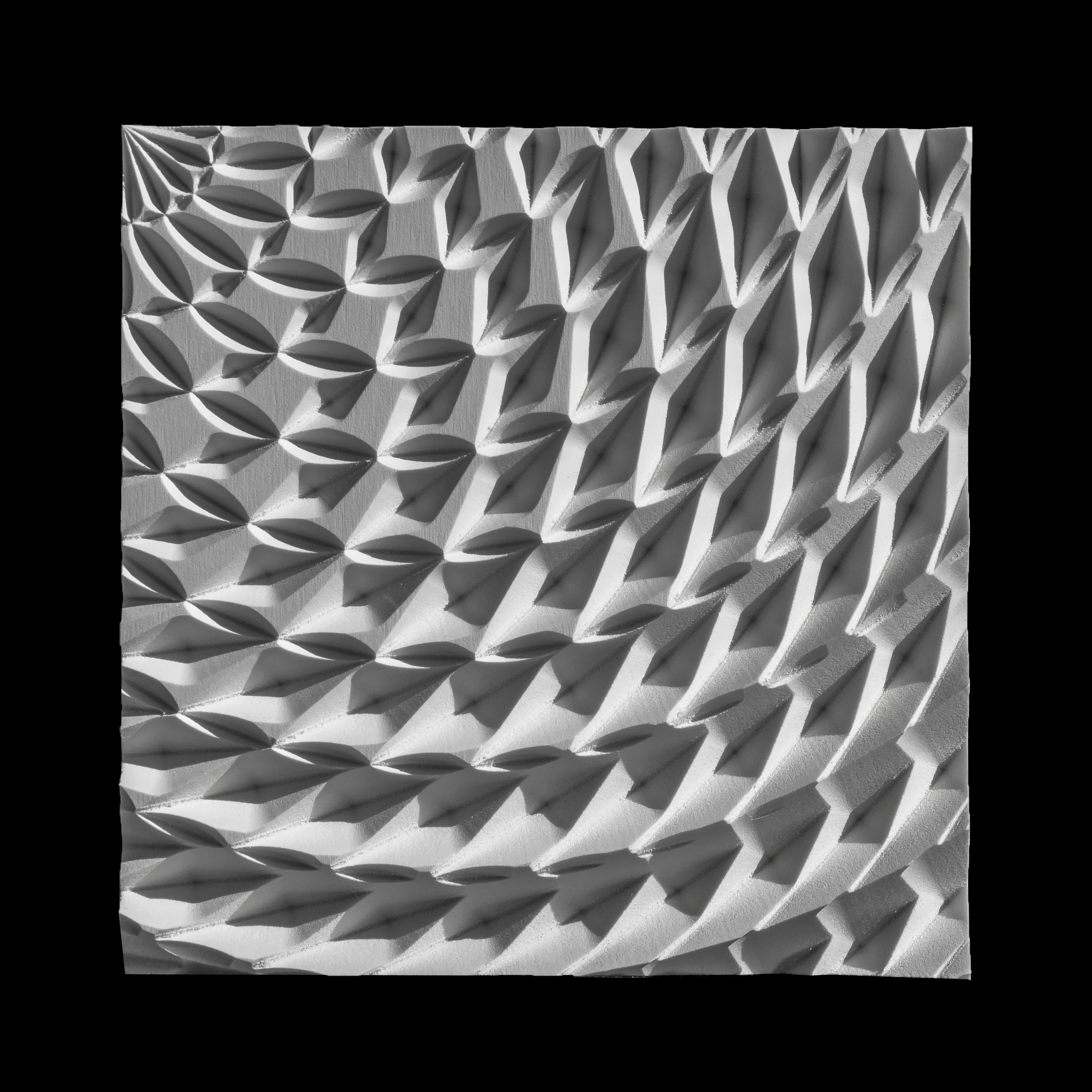

df.3d machining

Superficial and volumetric subtractive operations with a CNC milling machine:

General CNC and hardware instruction.

Toolpath coding.

Analysis, experimentation and research based on a milling project with small and large machines.